Are you looking for a way to make your needle? It’s not as difficult as it may seem! Follow this simple guide to make your very own needle.

Making a needle at home may seem impossible to many people, especially if you need the right tools. Fortunately, with just some basic materials that can be found around your house or garage, it is possible to craft a needle and use it for various purposes.

This blog post will focus on the steps necessary how to make a needle – from gathering supplies and understanding how metal wire works to cutting and filing down the wire into shape – ensuring that you end up with something both functional and aesthetically appealing. Let’s get started!

What Will You Need?

Before you can make a needle, you’ll need to gather the right supplies. You will need:

- Metal wire (any gauge of wire will do)

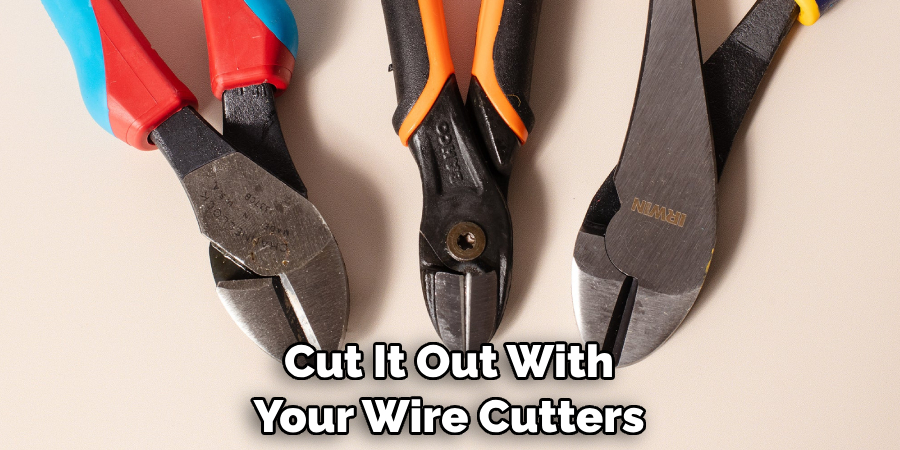

- Wire cutters

- Needle file

- Safety glasses (to protect your eyes while working with metal wire)

- Marker or pen to mark the needle shape on the wire.

Once you have all of the necessary materials, you can begin to shape your needle.

10 Easy Steps on How to Make a Needle

Step 1. Understanding Metal Wire:

Now that you have all of the supplies, it’s time to start understanding how metal wire works. Metal wire comes in various gauges, so make sure you choose one suitable for your project. It is also important to understand how metal behaves when heated – if it gets too hot, it will become brittle and break easily.

To avoid this, use protective eyewear when cutting and filing down the metal wire. Consider using a heat sink if you are using a tool that produces a lot of heat.

Step 2. Mark the Needle Shape on the Wire:

Using your marker or pen, draw out the shape of the needle on the metal wire. Make sure to leave some extra material at the end for filing down and sharpening later. If you need help figuring out the size and shape of the needle, you can always reference an existing needle for reference.

Step 3. Cut Out Your Needle Shape:

Once you have marked out your desired needle shape, it’s time to cut it out with your wire cutters. Be careful not to press too hard, as this can damage the wire and make it harder to work with. Use an adjustable tension cutter which will help produce more precise cuts.

Step 4. File Down the Edges:

Using your needle file, smooth down any rough or uneven edges on the wire. This will help ensure that the needle is free of sharp edges and has a more professional look. Remember to wear your safety glasses during this step!

Step 5. Re-cut any Necessary Lines:

If you find that certain lines don’t match up as well as they should, re-cutting them with your wire cutters may be necessary for a more precise fit. Once again, be careful not to press too hard, as this can damage the wire. As with the previous step, use an adjustable tension cutter if possible.

Step 6. Check the Needle Shape:

Once you have finished filing and cutting the wire, it’s time to look at your needle shape. It should be symmetrical with no rough or uneven edges. If not, you can go back and re-cut or file down any areas until it looks perfect.

Step 7. Heat Treat Your Needle:

Heat treating your needle will help make it more durable in the long run. To do this, heat up a metal block or anvil and then place the needle on top of it for several seconds before removing it and allowing it to cool down naturally. This will help ensure that your needle is strong and sturdy enough to use in a variety of applications.

Step 8. Sand and Polish the Needle:

Using a fine sandpaper, polish down any rough edges or imperfections on your needle. This will help make it look more professional and reduce the risk of it snagging on any fabrics you may be using. Be careful not to press too hard, as this can damage the wire.

Step 9. Final Check:

Now it’s time to take one last look at your needle and make sure everything looks good before you use it. Look for any sharp edges that may need to be filed down and ensure all of the lines are symmetrical with no gaps or irregularities. Ensure that the needle is strong and durable enough for its intended use.

Step 10. Use Your Needle:

Congratulations! You have successfully crafted your needle! Now use your new needle for whatever project you had in mind.

Now that you know how to make a needle, why not try making some more? With the right supplies and techniques, it can be easy to craft your own needles at home. So get creative, and let us know what you come up with!

5 Additional Tips and Ticks

1. Gather the right supplies. You will need a wire, such as a piece of stainless steel or copper, pliers, and a hammer.

2. If you are using stainless steel, you should anneal it first. Simply place the wire in a heat-resistant container and apply a torch until it is orange in color. This will make it easier to shape.

3. Take a pair of pliers and form the wire into the desired shape. You can make a blunt tip by hammering the end flat or create more of a point by partially wrapping the end around your finger and then snipping off any excess with scissors or tin snips. Ensure all edges are smooth and rounded so they won’t be sharp against your skin while working with fabrics.

4. To finish your needle, use sandpaper on both sides of the shaft to smooth out the surface and ensure it is symmetrical. This will help ensure it passes through fabrics without catching or snagging.

5. Finally, you can use a file to sharpen the needle’s tip if desired and create more of a point for finer fabrics like silk or satin. After your needle is complete, be sure to disinfect it with rubbing alcohol before using it on any fabric. This will help protect against any contamination from germs or bacteria.

With these tips, you’ll be well on your way to a perfect homemade needle!

5 Things You Should Avoid

- Avoid using plastic, aluminum, or any other soft metal for your needle. These materials can easily be bent or broken and won’t hold their shape over time.

- Don’t try to sharpen the tip of the needle with a knife or scissors, as this could create a jagged edge or poke holes in your fabrics.

- Never attempt to anneal wire without proper ventilation and safety equipment such as gloves and a face mask since the fumes from melting metals can be dangerous.

- Refrain from trying to heat the wire directly by putting it in a fire, which could cause it to melt, making it impossible to use for sewing projects.

- Remember to disinfect the needle after you make it. This is necessary to ensure your homemade needle is safe and free from contaminants.

By following these tips, you can create a strong, durable needle that will last many years!

How Do You Bend a Needle?

- Start by placing the wire on a flat surface and using pliers to create a bend in the middle of the needle.

- Then, take a hammer and gently tap along the curve while supporting it with your other hand until you have the desired shape.

- Lastly, use sandpaper on both sides of the shaft to ensure that there are no sharp edges or points that could snag against the fabric when sewing.

By using these steps, you can bend your needle into whatever shape is necessary for each project! This can become an easy task with practice and patience as you get more comfortable with shaping metal. Happy crafting!

How Do You String a Needle?

- Start by sliding the thread through the eye of the needle, making sure that it is firmly in place. You may need tweezers for this step if the eye is too small to fit your fingers.

- Next, take one end of the thread and pass it through a loop so that you can secure it with a knot at the base of the needle shaft.

- Finally, tie another knot at the top of the needle near the pointy tip to ensure your thread does not slip off as you stitch and sew fabrics together.

By using these steps before starting any project, you can easily string up a needle and avoid any unnecessary frustration when trying to finish a garment or quilt. With practice, you’ll be able to do this without even looking!

Conclusion

Crafting a needle alone is not easy, but it can be gratifying. This step-by-step guide gives you the necessary knowledge to create the perfect needle. Take it slow, and don’t be afraid of making mistakes – it takes practice to master this skill. Whether you plan to use your new handmade needle for a sewing project or other creative endeavor, think of it as an expression of your artistry.

As with any form of craftsmanship, the more patience and dedication you apply to your work, the more satisfaction and pride you will take away from the end product. So get creative with different materials and designs to craft a unique needle that shines with its delightful character!

Hopefully, the article on how to make a needle has given you the confidence to take on this project and create something special! Good luck!