Are you ready to take your sewing skills to the next level? From power buttonholes and couture garments to intricate quilting designs, sewing with sew-in interfacing can be a great way for experienced tailors and beginners alike to add structure and support to their projects.

Sew-in interfacing is an essential tool that should never be overlooked or underestimated – it has the potential to make or break a garment’s look, but don’t worry! We’ll break down how sew-in interfacing works so that you can easily master this technique.

With just three simple steps on how to use sew in interfacing, you too can learn how this pro-level stitching method will help take your fashion ideas from concept to creation. Let’s get started!

Needed Materials

Given below are all the materials you will need in order to use sew-in interfacing for your project:

- Sewing machine

- Thread

- Scissors

- Interfacing fabric

- Iron and ironing board

11 Simple Step-by-step Guidelines on How to Use Sew in Interfacing

Step 1: Prepare the Fabric

Before you begin, it is important to make sure that your fabric is properly prepared. Cut out the pattern pieces for the garment and press them with an iron. This will ensure that any wrinkles or creases are removed before interfacing is applied. This step is essential in order to get the best results. But don’t worry, pressing fabric is easy!

Step 2: Cut Out the Interfacing Pieces

Next, use the pattern pieces that you have already cut out as templates to cut out interfacing pieces that are the same size and shape. It is important to ensure that you have cut out enough pieces, as too few will cause your garment to lose structure. It is also important to make sure that any edges you have cut are smooth and even.

Step 3: Interfacing Placement

Now that the pieces are cut out, it’s time to apply them to your fabric. Place the interfacing on the wrong side of the fabric pieces, making sure that they are placed exactly where you need them for support.

If you need to, use pins or clips to keep the interfacing in place. It is also important that you take into account any pattern direction and grain line markings that may be on the fabric when placing the interfacing pieces.

Step 4: Ironing

Once your interfacing is placed, it’s time to apply heat in order to adhere it to the fabric. Set your iron on low and use a dry heat setting, or follow the instructions that come with the interfacing product. Take extra care when pressing the interfacing in place, as too much pressure can cause it to become distorted.

Step 5: Trim and Secure Edges

Now that your interfacing is in place, you will need to trim away any excess fabric from around the edges. This can be done with scissors or a rotary cutter. Make sure that all of the seams are secure and there are no loose threads. However, be careful not to cut too close to the stitching line as this could cause the interfacing to come loose.

Step 6: Sewing

Once your interfacing is in place and trimmed, it’s time to begin sewing. Use a straight stitch or zig-zag stitch to sew the interfacing in place and make sure that all of the edges are secure. This step is important, as it will ensure that your garment has enough structure and support.

Step 7: Press Seam Allowance

After you have finished sewing the interfacing in place, it’s time to press the seam allowance. This will help ensure that you have a nice, crisp edge on your garment and will also help keep the interfacing in place for a longer period of time. It is important to use a protective cloth between the iron and the fabric, as some interfacing can be sensitive to heat.

Step 8: Check for Wrinkles

Before moving on to the next step, make sure that there are no wrinkles or creases on the interfacing. If there are, use a steam iron to remove them or use an ironing board to flatten them out. You may also want to run a second row of stitches along the seam line to secure the interfacing in place.

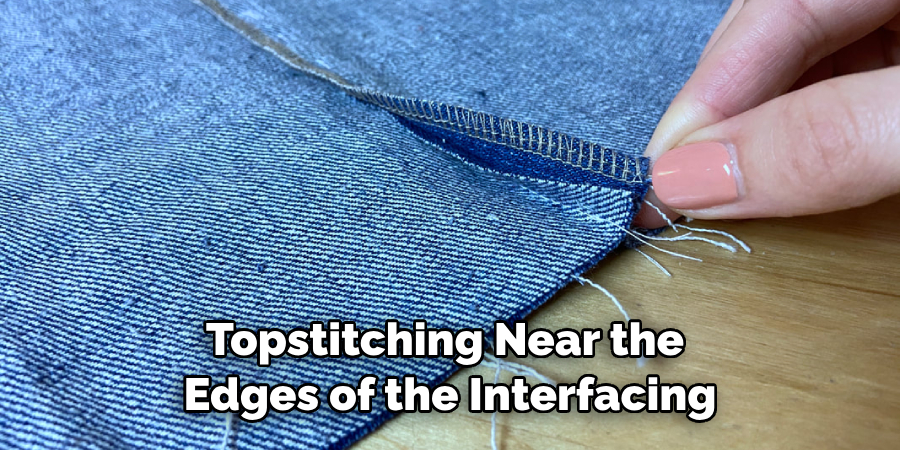

Step 9: Topstitching

If you want your garment to have a professional-looking finish, consider topstitching near the edges of the interfacing. This will help ensure that all areas of the fabric are securely attached and that your garment looks polished. If you are using an invisible zipper, this is also a great way to prevent it from shifting while you’re wearing it.

Step 10: Allow Time to Cool

Once you have finished topstitching, it is important to allow time for the fabric pieces to cool before moving on. This will help ensure that all of your hard work has paid off and there are no wrinkles or creases in the fabric. This step is particularly important if you have used a steam iron, as the fabric may still be slightly damp.

Step 11: Put Together Your Garment

Now that your fabric pieces are reinforced with interfacing, it’s time to put the garment together! Follow the instructions for your pattern and use any extra techniques you have learned from this guide to ensure that you have a finished product that is both stylish and professional.

Following these simple steps on how to use sew in interfacing will help you create garments that are durable, stylish, and professional-looking. Don’t be intimidated by this technique – with a little practice and patience, you too can become an expert at using sew-in interfacing. Now get out there and show off your newly acquired skills!

Some Tips

Here are some helpful tips when working with interfacing to ensure you get the best results:

- Always Test a Small Swatch of Interfacing on a Scrap Piece of Fabric Before Using It on Your Project.

- Use an Ironing Board and Press Cloth When Pressing the Interfacing Onto the Fabric.

- When Cutting Out Pieces, Make Sure That You Have Enough for All Areas That Need Reinforcement but Not So Many That They Become Too Bulky.

- Take Into Account Any Pattern Direction and Grain Line Markings When Applying the Interfacing.

- For Best Results, Use a Straight Stitch or Zig-zag Stitch to Sew the Interfacing in Place.

- Allow Time for Your Fabric Pieces to Cool Before Moving On.

- Consider Topstitching Near the Edges of the Interfacing for a Professional-looking Finish.

- Use a Steam Iron to Remove Any Wrinkles or Creases in the Fabric Once It is Finished.

- Take Your Time and Practice This Technique – With Patience, You Will Become an Expert!

Using sew-in interfacing is a great way to reinforce and add structure to your garments. With these tips and techniques, you can create professional-looking pieces that will last for many years to come. So get out there and start experimenting! With a little practice, you too can become an expert in no time.

Frequently Asked Questions

Q: How Do I Know Which Type of Interfacing to Use?

A: The type of interfacing you choose will depend on the fabric that you are using and what look or feel you want for your project. Generally speaking, woven fusible interfacing is best used on heavier fabrics such as denim, wool, twill, velvet, corduroy and canvas. Non-woven fusible interfacing is best used on lighter fabrics such as silk, chiffon, cotton, and linen.

Q: How Do I Know When the Interfacing Adheres to the Fabric?

A: You will know if the interfacing has been properly adhered to when you can no longer see any wrinkles or creases on the fabric. To test this, simply press down lightly with your finger and if there are no indentations or movement, then the interfacing has been successfully applied.

Q: How Can I Keep My Interfacing From Shifting or Moving?

A: To prevent your interfacing from shifting or moving, you can use pins or clips to keep it in place while applying the iron. You can also stitch along the edges of the interfacing after it has been applied if you are concerned about it not staying put.

Finally, you can use fabric glue or spray adhesive to keep the interfacing secure. Just be sure to follow the instructions on the product for best results.

Q: How Do I Remove Interfacing From My Fabric?

A: If you need to remove interfacing from your fabric, you can do so by using a seam ripper to carefully cut the stitching and then peel it away. It is important to take your time when doing this as too much force can cause damage to the fabric.

You may also want to use a steam iron to help loosen the adhesive before attempting to remove it. Once all of the interfacing is removed, you can then press down lightly with your finger to make sure there are no remaining pieces left behind.

Conclusion

Sew-in interfacing is a great fabric stabilizer that can help give clothing or other sewn items an extra level of support. When used correctly, this amazing product can even transform an item to better fit the wearer and add more structure to lightweight fabrics.

It’s a highly beneficial addition to one’s sewing toolkit that can make any project look customized and professional.

With practice comes perfection, so if at first you don’t succeed with sew-in interfacing–try again! With patience and determination, anyone can get the hang of manipulating this useful material into their projects—it just takes some planning.

So take some time to study up on how to use sew in interfacing properly before attempting a complex piece or pattern. Who knows? You may find yourself becoming a whiz at using sew in interfacing no time!