Vinyl heat transfers have become increasingly popular for creating custom designs on shirts, providing a quick and easy way to add personalization and style. However, one common issue that many crafters face is vinyl peeling off shirts after some wear and washing. This can be frustrating, especially when you’ve invested time and effort into making your designs. But fear not!

In this article, we will delve into the essential tips and tricks on how to keep vinyl from peeling off shirts, ensuring that your creations stand the test of time and maintain their vibrant appeal.

With a few simple techniques and proper care, you can enjoy long-lasting, beautifully customized shirts that will withstand countless washes and wear. Let’s dive in and discover the secrets to preserving the integrity of your vinyl designs.

The Popularity of Using Vinyl for Shirt Designs and Customization

Vinyl has become an increasingly popular choice for creating custom designs on clothing. It is available in a variety of colors, styles, and textures to suit any look you’re going for. However, one common issue that comes up when applying vinyl to fabric is that it can peel off over time if not applied correctly.

Fortunately, there are some simple steps that you can take to ensure that your vinyl stays secure and looking great for years to come.

The first step in keeping vinyl from peeling off clothes is to make sure that the fabric is clean before applying the vinyl. Any dirt, oils, or other contaminants on the surface of the fabric can interfere with the adhesive on the back of the vinyl and cause it to not adhere properly.

For best results, you should wash the fabric in a gentle detergent without fabric softener and allow it to air dry before applying the vinyl.

The second step is to make sure that you apply enough pressure when ironing on the vinyl. This will help ensure that the adhesive bonds properly with the fabric, preventing peeling over time. If possible, use a professional heat press to apply your vinyl for even pressure and consistent results.

However, if you are using an iron, make sure to use the correct temperature setting for the type of vinyl you are using so that it does not melt or become distorted.

The Common Issues of Vinyl Peeling off Shirts and Its Impact on the Design’s Longevity

Vinyl is a great material for making custom designs on t-shirts, but if not taken care of properly it can start to peel off. This issue often occurs due to improper application or when the garment has been subjected to frequent washing and ironing at high temperatures. If your vinyl design begins to peel off, it can compromise its overall appearance and longevity, lowering the overall quality of your product.

Fortunately, there are some simple steps you can take to help ensure that your vinyl design stays in place for a longer period of time.

First and foremost, be sure to use a heat press when applying your vinyl onto the shirt. Heat presses provide even pressure and temperature throughout the entire application process which helps keep your design firmly in place.

Once the design is applied, be sure to take care of it properly to ensure its longevity. Never iron or dry clean your garment as this can cause the vinyl to peel off prematurely. Instead, machine wash the shirt with cold water and on a gentle cycle. Additionally, be sure to turn it inside out before washing and hang dry afterwards so that the design is not subject to direct heat or agitation.

10 Methods How to Keep Vinyl from Peeling off Shirts

Method 1: Choose High-Quality Vinyl

The first step in ensuring your vinyl designs stay put is to invest in high-quality vinyl. Cheaper vinyl may not adhere as well to the fabric and can peel off more easily. Look for reputable brands that offer durable and long-lasting vinyl options specifically designed for use on fabric. Quality vinyl will not only adhere better but also retain its vibrant colors and design integrity over time.

Method 2: Select the Right Vinyl Type for the Fabric

Different fabrics have varying textures and compositions, which can affect the adhesion of the vinyl. For best results, choose the appropriate type of vinyl for the fabric you’re working with.

For example, heat transfer vinyl (HTV) is ideal for cotton and polyester fabrics, while adhesive vinyl is better suited for hard surfaces like mugs or glass. Always check the vinyl manufacturer’s recommendations for the compatible fabric types to ensure a secure bond.

Method 3: Prepare the Shirt Properly

Properly preparing the shirt before applying the vinyl is crucial for a long-lasting bond. Start by washing and drying the shirt to remove any sizing or residues that may interfere with the adhesive. Avoid using fabric softeners or dryer sheets, as they can leave a waxy residue. Additionally, make sure the shirt is completely free of wrinkles, as vinyl adheres better to a smooth surface.

Method 4: Use the Right Heat and Pressure

When applying heat transfer vinyl, using the correct heat and pressure settings on your heat press or iron is essential. Follow the manufacturer’s instructions for the recommended time, temperature, and pressure settings.

Applying too little heat or pressure can result in a weak bond, while excessive heat or pressure can damage the vinyl or the fabric. Finding the right balance ensures a strong and durable bond between the vinyl and the shirt.

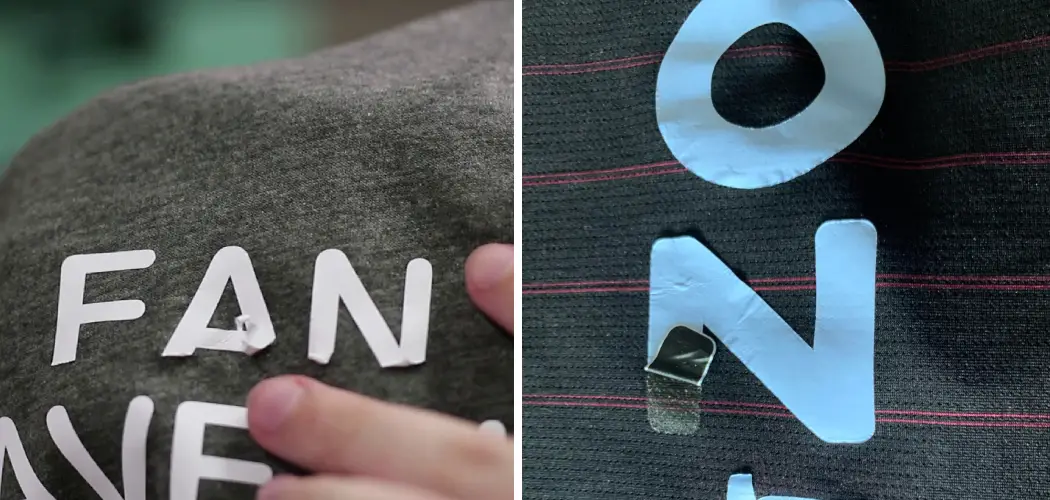

Method 5: Peel the Carrier Sheet Properly

After heat pressing the vinyl onto the shirt, it’s essential to peel the carrier sheet off correctly. Wait for the vinyl to cool down before peeling off the carrier sheet. Peel it slowly and at a 180-degree angle, ensuring the vinyl adheres well to the fabric. If you notice any areas where the vinyl didn’t stick, lay the carrier sheet back down and apply more heat and pressure to those specific areas.

Method 6: Add a Heat Transfer Cover Sheet

A heat transfer cover sheet, also known as a Teflon sheet or parchment paper, can be used as an additional layer of protection when heat pressing the vinyl. Placing a cover sheet over the vinyl and shirt prevents direct contact between the heating element and the vinyl, reducing the risk of scorching or damaging the vinyl during the application process.

Method 7: Wash and Dry the Shirt Properly

Proper care after applying the vinyl is crucial for its longevity. When washing the shirt, turn it inside out to protect the vinyl from friction with other garments or the washing machine’s agitator. Use a mild detergent, and opt for a gentle cycle with cold water to prevent unnecessary wear and tear.

Avoid using bleach or harsh chemicals, as they can degrade the vinyl adhesive. After washing, tumble dry the shirt on low heat or air dry to avoid exposing the vinyl to excessive heat.

Method 8: Avoid Using Fabric Softeners and Dryer Sheets

Fabric softeners and dryer sheets can leave a residue on the shirt that interferes with the vinyl’s adhesive properties. To maintain a strong bond, avoid using fabric softeners or dryer sheets when washing or drying vinyl-decorated shirts. Instead, opt for products specifically designed for use with heat transfer vinyl or simply skip the fabric softener altogether.

Method 9: Store Shirts Properly

When not in use, store your vinyl-decorated shirts properly to prevent peeling and damage. Hang them on a hanger or fold them neatly in a drawer, avoiding tight creases that could cause the vinyl to peel off. If you’re stacking shirts, place a piece of parchment paper between them to prevent the vinyl from sticking to other surfaces.

Method 10: Perform a Test Run

Before embarking on a large-scale project, it’s always a good idea to perform a test run on a scrap piece of fabric. This allows you to experiment with heat and pressure settings, as well as test the adhesion of the vinyl. It also helps you identify any issues or adjustments needed before applying the vinyl to the actual shirts, saving you time and materials in the long run.

Conclusion

In closing, keeping vinyl from peeling off shirts is possible with preparation and proper techniques. Start by choosing the right type of shirt and prepping it with an adhesive primer to help keep the vinyl from loosening.

Once the shirt is ready, place an iron-on transfer on it and turn both the heat press temperature setting and duration as high as recommended for that specific material. Make sure to maintain pressure during the entire heating process for even and consistent adhesion.

Finally, remember to lay a protective sheet over your design before heat pressing to avoid any melting or burning of your vinyl graphics. By following these steps, you will be able to create beautiful shirts with vibrant designs that will remain in place long after washing. Now that you know how to keep vinyl from peeling off shirts, look forward to achieving more creative endeavors!